Top Guidelines Of American Plastics

Not known Facts About American Plastics

Table of ContentsThe 4-Minute Rule for American PlasticsThe 3-Minute Rule for American PlasticsAmerican Plastics Fundamentals ExplainedRumored Buzz on American PlasticsThe Buzz on American Plastics

A little research can assist you with time. It is challenging to evaluate its top quality at initial glimpse with the appearance of HDPE pipeline installation, lots of issues are revealed when using, so we can just have an appropriate judgment after use. For that reason, it is essential to select HDPE pipeline fittings made by a professional supplier with a good track record and reputation.

A technical professional is necessary for an excellent product, especially in the manufacturing sector, because a little error will certainly bring about the failure of the entire project. HDPE pipes can change concrete pipelines in field systems to conserve time and price of repairing broken or burst pipelines. HDPE pipeline is additionally a much less expensive option compared to various other piping materials in terms of operating and setup expenses.

The smart Trick of American Plastics That Nobody is Talking About

HDPE pipelines are made with strong straight or rounded sections. The pipes are not weak and can be easily put into a bent area without extra jointing or welding.

It has reduced stress and unstable turbulence, particularly at high flow prices. Its 'non-adhesive' characteristic makes it ideal for preserving the buildings of hydraulic liquids. Also HDPE tin tubes are developed in 2 stages to ravel the interior. Chemicals immune to HDPE pipelines can pollute the pipeline. The pipeline does not collaborate with chemicals and does not melt heat or electrical power.

HDPE pipelines are normally strong and resistant to damages caused by outside loads, high pressure or vibration - https://profiles.delphiforums.com/n/pfx/profile.aspx?webtag=dfpprofile000&userId=1891266661. The pipes can endure handling and bend even in winter. Safe eyeliner HDPE internal tubes Smooth Line Pipeline Sliding lining utilizing roller mixes Pipe explosion Plastic plumbing systems Building and construction of brand-new pipes Corrosion resistance, no dripping, high longevity

Warmth combination, while its difficulties exist, can develop strong and trustworthy joints. Responses: The strength and resilience of HDPE can be gauged by its ability to hold up against temperature levels of around 248F in the short-term or even a consistent 230F. If your application includes gas and liquid to gain access to and elevate those temperatures, HPDE piping is a dependable remedy.

The American Plastics Diaries

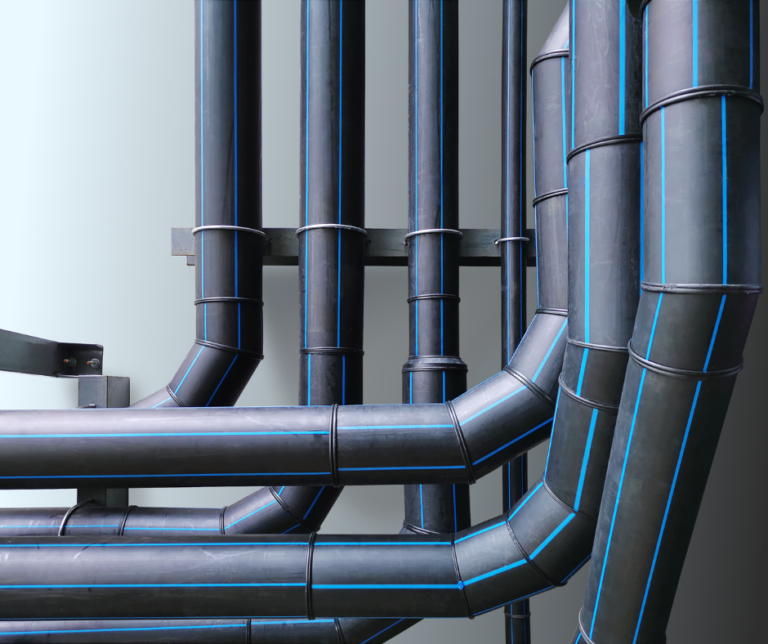

A safe and clean water line/potable water pipeline is constantly dark with blue red stripes and pipelines passing with fluids, liquids under stress, and process gases are always filled up with a yellow or black jacket with yellow lines. HDPE pipe product have been used in the basic sector for over 50 years and their results are astounding, constructing self-confidence among manufacturers that they are much more focused on HDPE pipe options.

Times considering that 1991 Elimination of material needs with gauge and change. In the stress and anxiety fracture resistance examination the cell division demands were deteriorated. It is sensible to wrap up that HDPE pipe built today might have.

Each dimension group is made remembering the requirements of pressure, flow rate, and ecological aspects of the designated application. By matching the appropriate HDPE pipe size to its usage, designers and professionals can optimize efficiency and expand the life expectancy of their piping systems. Dimension and diameter are related concepts in the context of HDPE pipelines.

Get This Report about American Plastics

As specified earlier, pipes with lower SDR worths are able to endure greater stress, which is an important factor to consider in the choice procedure for projects that entail high pressure or critical applications. high quality hdpe pipe. Choosing a pipe with an improper SDR can result in system failing, safety dangers, and costly repairs. Choosing the proper HDPE pipeline dimension is important for the success and performance of any type of piping system

Application Specifics: Customize your pipe size selection visit our website to the particular requirements of its application, whether for metropolitan, industrial, or various other usages. Understanding exactly how the HDPE pipeline will certainly be used, the expected circulation prices and the stress requirements are essential. For circumstances, high-pressure applications may need a pipe with a better wall surface density to endure the internal anxieties, while a lower-pressure, high-flow system might focus on diameter size to reduce friction loss.

The Best Guide To American Plastics

Adhere to these steps: Examine the Application: Determine the pipe's meant usage, including ecological factors and service problems. Refer to SDR: Examine the basic measurement proportion to discover a pipeline that can take care of the required stress.

Picking the right HDPE pipeline size is a fragile balance in between many technological specifications and practical needs - https://www.tumblr.com/americanplastics/794991014367690752/at-american-plastics-we-manufacture-4-12-dr-11?source=share. However, with careful factor to consider and precise calculations, you can make sure the dimension of the pipe you choose will serve your demands effectively and efficiently. Choosing the right HDPE pipe size is important for system effectiveness, durability, and cost-effectiveness

Understanding these facets will make certain ideal performance and compatibility throughout your piping system - hdpe pipe in stock Midland TX. The expected circulation price or volume of the liquid being transferred is one of the key components in pipeline size selection. A pipe that is also tiny can restrict flow, triggering pressure loss and prospective obstructions, while an excessively huge pipe might lead to unneeded expense and minimized system efficiency